|

Dongguang County Bai tong Plastic Products Co.,Ltd.

|

Proportional Pressure Control Automatic Blow Molding Machine for Bucket / Plastic Bottle Making

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

water oil or chemical raw material bucket etc plastic bottle making machhine

<span style="fon

water oil or chemical raw material bucket etc plastic bottle making machhine

Electric control system: Japan matsubishi PLC and human-computer interface(Chinese and English) control. Color touch screen operation, adopt the SIEMENS temperature control module. All process setting, changing, searching, monitoring, fault diagnosis can be operation on the touch screen ,no point contact work principle, and the electric parts is more durable. standard electric control cabinet, makes the component runtime environment stability, extend the service life of the equipment.

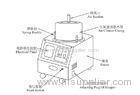

Hydraulic system: Proportional pressure control equipped with imported famous brand hydraulic value and pump, stable and reliable.

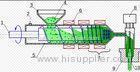

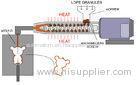

Plasticization system : efficient plasticizing mixing screw, ensure plastic plasticizing completely and evenly.

Speed regulating system : frequency control and hard alloy tooth surface reducer casing. Smooth speed, energy saving, low noise and durable.

Molding clamping sliding structure adopts linear guide way, accuracy up to micron level. The whole mold clamping combining a high position accuracy, easy and energy saving and strong bearing, immutability. Patented products: three rod, single cylinder two-way synchronous mold clamping structure, stability is good.

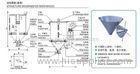

Adopting the parison programmer, reducing the differences on the width of the up and down due to reducing material and vertical tensile, and improve the uniformity of the wall thickness efficiently.

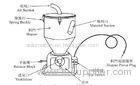

Die-mold: Using the best quality material, like the 38CrMoALA, 42CrMoV, 35CrMo.Through precision machining and heat treatment.

Mold changing more easy: the die-mold can be lift up and down, backward and forward with the machine plate (hydraulic control),for saving more space to install all kinds of molds. die-mold up and down, for adjusting the mold mouth and the mold distance, reduce the material waste.

Energy saving: while the speed is 70% of the nominal speed, the power consumption is 110kw/h, and energy saving 20kw/h than the old machines.

Technical Specification

|

Specification |

units |

BT120 |

BT120L |

BT120XL |

BT120XXL |

|

Material |

|

PE.PP.ABS |

PE.PP.ABS |

PE.PP.ABS |

PE.PP.ABS |

|

Max. Container capacity |

L |

250 |

350 |

500 |

1000 |

|

Screw diameter |

MM |

Φ120 |

Φ120 |

Φ120 |

Φ120 |

|

Clamping force |

KN |

700 |

1000 |

1500 |

2000 |

|

Platen Size |

MM |

1200*1600 |

1400*1800 |

1800*2000 |

2000*2600 |

|

Max. Mold dimension (W x H) |

MM |

800*1600 |

1000*1800 |

|