|

Dongguang County Bai tong Plastic Products Co.,Ltd.

|

Gold Index: 5423

High Speed Extrusion Blow Molding Machinery for Rotational Molding Plastic LDPE Ice Pop Tube

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

BT-120 connection type Automatic plastic bottle blowing machine

BT-120 connection type Automatic plastic bottle blowing machine

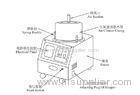

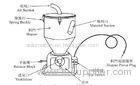

This machine mainly used in the side inlet plastic packing . Such as: medicine bottles, fruit milk bottles, beverage bottles, cosmetics bottles etc plastic products. Translator part is used frequency control . This machine unit adopted screw extrusion blowing process, automatic temperature frequency control. This unit used electric, pneumatic and mechanics all in one machine, steady performance, conveniently operation, is a ideal substitute for manual production.

- Suit for producing different size of milk bottle , soy sauce bottle, yellow wine bottle. different size of shampoo bottle, body wash bottle, detergent bottles and others toiletries and different children’s toys.

- Optional pearly –lustre layer co-extrusion system.

- According to the product size. Select different cavity of die head.

- According to the different material, optional JW-DB single station hydraulic screen-exchanger system.

- According to customer’s requirement. Optional auto-deflashing on line, scrap conveying on line, finished product conveying on line and others.

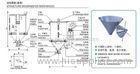

main technical parameters

|

Model |

BT(4,6)molds rotational bottle blowing machine |

Max. capacity |

1000ml |

|

Screw diameter |

55mm(38CrMoALA) |

screw heating power |

11kw |

|

Rotational power |

0.75kw(4 molds) 1.1kw(6 molds) |

Main motor power |

7.5kw(frequency) |

|

Screw L/D ratio |

25:1 |

Max. Production diameter |

80mm |

|

Economic speed |

1500-5000pcs/h |

Max.Platen open width

|

120mm |

|

Mold open width |

120mm |

platen distance |

118-120mm |

|

Mold available size W*H*T |

125*300*118mm |

Platen Size W*H*T |

140*225*20mm |

|

Gas consumption |

0.4-0.7m³min |

Material |

PE/pp |

|

cutting type |

Hotting cut/doctor knife |

Clamping force |

30KN |

|

Speed adjust type |

frequency adjust |

Operating system |

PLC |

|

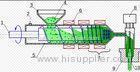

Machine size W*H*T |

3300*1200*1500mm |

Blowing type |

Low blowing,side blowing |

servise

1. An experienced engineer can be dispatched to help you for installation and commissioning in your factory, usually all the job can be done in one week.

2. We can provide operation training to your engineer or workers, including routine operating, data setting, mould installation, producing line arrangement, working flow, routine maintenance and simple repairs.

3. One year guarantee time and necessary spare parts to insure your machine’s working stability. Remote technical support and experience sharing cover a machine’s whole lifespan.

4. If you have questions before investing a new product project, welcome to contact us for consultation!

[1] Q:Are you a trading company or a manufactory? For example- blow molding machine

machine

A: We own a factory ourselves, and we can assure the quality we manufactured.

[2] Q: Where is your factory located?

A:our company is in Hebei province three hours’ driving from Beijing airport to our company.

[3] Q: How about quality control in your factory?

A: “ Quality is the key point, do what customers need”

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Dongguang County Bai tong Plastic Products Co.,Ltd. [China (Mainland)]

Business Type:Manufacturer

City: Cangzhou

Province/State: Hebei

Country/Region: China (Mainland)

You May Like:

Sitemap XML

About HiSupplier Help Center Customer Service Friend Links Site Map Archives

Browse by: China Suppliers - Hot Products - Products Directory - Offers Directory - Suppliers Directory - Buyers Directory

Language Option: العربية - Nederlands- Français- Deutsch- Italiano- 日本語- 한국의- Português- Pусский- Español