|

Dongguang County Bai tong Plastic Products Co.,Ltd.

|

Raw Materials Vertical Color Plastic Mixer Machine For Plastic Bottles Blow Molding Machine

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Raw Materials Vertical Color Plastic Mixer Machine For Plastic Bottles Blow Molding Machine

<p style="text-align:c

Raw Materials Vertical Color Plastic Mixer Machine For Plastic Bottles Blow Molding Machine

plastic raw material mixer machine

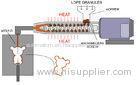

1. Brief introduction of plastic raw material mixer machine :

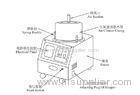

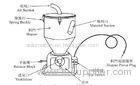

1. Drying by normal drying machine, since the material is still, hot wind penetration is insufficient, the material is partially heated, the material will agglomerate easily and result in jams and blocks, so complete dry effect can not be reached. The design of this machine includes two stages of spiral rapid transports. The first stage is to move the raw material to the barrel. The second stage is to rapidly lift the material to the top of barrel and scatter it in shape of umbrella. Hot wind will blow around from the center of the bottom of the barrel. Hot wind will blow around from the center of the bottom of the barrel. Hot wind will blow upwards and penetrate the raw material, dynamic drying with complete heat exchange is conducted.

2. Since the raw material in the barrel is continuously rolling, hot wind is continuously blowing from the center,so mixing and drying is synchronously conducted,so it saves time and power.Ifdrying is not needed,dry switch can be turned off,then the machine has only fuction of mixing.this machine can also be used for mixing of granulate material and powder material.

3. The barrel body,spiral vanes,shaft,cylinder,support frame and the parts which touch the raw material are all made of stainless steel.

4. When the material need clearing,openthe material clearing opening and let the spiral vanes rotate in counter direction.Material clearing can therefore be sinply operated.

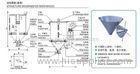

2. Parameters of plastic raw material mixer machine :

|

Model |

300L |

500L |

1000L |

2000L |

3000L |

5000L |

8000L |

|

Power source |

AC380V 50HZ 3P |

||||||

|

Load volume (kg) |

300 |

500 |

1000 |

2000 |

3000 |

5000 |

8000 |

|

Blower power |

0.55 |

0.75 |

1.5 |

2.2 |

3 |

4 |

5.5 |

|

Heating power |

19.8 |

25 |

36 |

42 |

48 |

56 |

72 |

|

Control method |

PID |

||||||

|

Mixing motor |

0.75 |

1.5 |

2.2 |

3 |

4 |

5.5 |

7.5 |

about us

[1] Q:Are you a trading company or a manufactory? For example- blow molding machine

machine

A: We own a factory ourselves, and we can assure the quality we manufactured.

[2] Q: Where is your factory located?

A:our company is in Hebei province three hours’ driving from Beijing airport to our company.

[3] Q: How about quality control in your factory?

A: “ Quality is the key point, do what customers need”

BAITONG machinery factory focuses on quality, quality control from beginning to the end. Every piece of goods is tested strictly before packing and delivery.

[4] Q: How about guarantee ?

A: One year guarantee.

[5] Q: Do you provide bottle blow mould and air compressor ?

A: Yes , we provide complete system and you will no need to find the suitable air compressor and chiller...etc..

[6] Q: What is the language of the PLC and touch panel?

A: Don’t worry, we will translate the language in English, Spanish or any other language, to make sure you will have an easy operation .

[7] Q:How many days will be finished after we pay the deposit?

A: Around 30-50 work days.

[8] Q:What packaging of machines after inspection before delivery?

A: 1. standard film packing

2. wooden case packing is available

3.one machine and some auxiliary equipment are in one container

4.check by clients before packing and shipment

5.clients' special packing request is available