|

Dongguang County Bai tong Plastic Products Co.,Ltd.

|

Gold Index: 5423

Automatic Double Station Bottle Blow Molding Machine For Making Oil Barrel Plastic Bottles

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

BT full automatic double-station bottle blowing machine

<span styl

BT full automatic double-station bottle blowing machine

Machine use

This machine main applied to all kinds of oil pot,laundry detergent pot,cleanser bottle,chemical use bottles,children chair,plastic tool box and so on. We can according to customer’s require to provide single die,double die. Base on customer’ needing can add machine hand and automatic deflashing set, realize on line detection and output, to meet the automatic requirement.

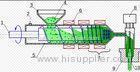

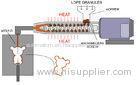

The structure of blowing machine

this type blowing machine in the structure we learned the advantage of Chinese and abroad factory, introduce the latest technology. The full machine design by computer. Base on the new structure design this type blowing machine save more power and energy.

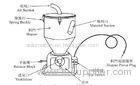

BT full automatic double location blowing machine made up of wall thickness control system,electric system,mould base system, hydraulic system four department.

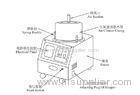

Machine body: composed of extruder ,blowing die head, jig institutions and gas blowing system. From the perspective of the path of raw materials, the plastic particle through the extruder heating,melting,mixing then feed into the die head: the melting plastic through the die head forming the initial rudiment; the rudiment feeding into the mold with blowing and cooling then get the final bottle.

Hydraulic system made up of extruder cylinder,wall thickness control cylinder,clamping cylinder,blowing needle cylinder four group. Machine body welding adopted carbon dioxide protect system, ensure the welding quality. After welding have been artificial buffing, can fully eliminate the weld, the welding parts are equipped with lifting device, the fuselage overall smooth, beautiful appearance.

Main Characteristic:

- Suit for producing different kinds of car urea box, tool box, automotive seat, auto air duct, auto flow board, bumper and car spoilers.

- Adopt high output extrusion system, accumulating die head.

- According to different material, optional JW-DB single station hydraulic screen-exchanger system.

- According to the different product size, customized the platen type and size.

- Optional hydraulic servo control system.

- Optional bottom sealing, take-out robot.

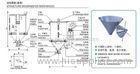

The main technical parameters

|

Model |

BT automatic double location blowing machine |

Maximum capacity |

10L |

|

Screw diameter |

80mm (38CrMoAla) |

Screw hotting power |

15kw |

|

Oil hydraulic pump power |

11kw |

Main motor power |

22kw |

|

Length to diameter ration(L/D) |

25:1 |

Max. Production (width X thickness) |

275x300 |

|

Economic speed |

180pcs/h |

platen max. open width |

650mm |

|

Mold open width |

230mm |

Die head heating power |

3kw |

|

Mold size |

325x350≥80 |

Platen side |

460x500x50 |

|

Thickness of mold |

160-320 |

Air blowing way |

Blowing up on bottle |

|

Air consumption |

0.5-0.8m3/min |

Raw material |

PE/PP |

|

Dongguang County Bai tong Plastic Products Co.,Ltd. [China (Mainland)]

Business Type:Manufacturer |